We get a lot of questions about intake manifolds, and because our recommendations vary depending on use and application – we thought it would be helpful to conduct a series of tests which demonstrate the several available intake manifolds back to back on the same engine. We hope these results will help our customers better understand where the various products fit in based on the desired operational RPM range.

The Engine

The Cylinder Heads

We then milled a set of our GPI – Ported OEM LS3 / L92 / L99 / LSA Port Cylinder Head Package to achieve a 10.5 to 1 compression ratio.

The Engine Management

We elected to perform the engine management functions with a Holley – Terminator LS MPFI Kit (550-610). This allowed for easy logging during pulls and closed loop fuel control at full throttle maintaining our target air / fuel ratio or 12.8 to 1 regardless of the changes to the induction systems.

The Camshaft

We began our testing with our GPI SS4 NFC camshaft. NFC representing “no fly cut”. This cam features the maximum amount of intake duration at a reasonable intake centerline, possible without adding or enlarging valve reliefs in the pistons for valve clearance. This cam is appropriate for testing the long runner manifold offerings and is one of our most popular.

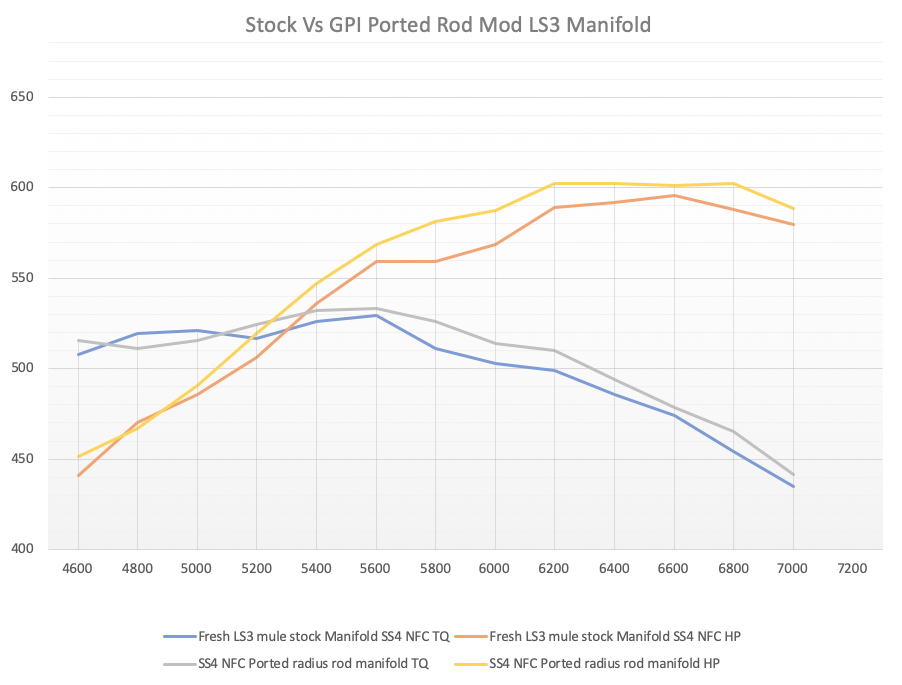

Stock LS3 Manifold (Baseline)

We began by installing a stock LS3 manifold and bringing our fresh engine up to operating temperature while monitoring its vital signs. (On a side note this block measured over .006 clearance on the #1 and #5 cam bearing with the others being from .003 to .004. We find this is common on the LS engine. GMs spec is .0015 to .003. Durabond offers each position in a .010 oversize OD providing an opportunity to machine the cam tunnel to the proper spec. Having performed this procedure our mule with a stock L99 GM oil pump ran 75 PSI thru the pull and hot idled with Driven BR 30 break in oil at 40 PSI.)

We then made half dozen pulls to seat the rings observing the power increase with each pull. After it appeared to level out, we made 3 back to back pulls establishing an average baseline.

Baseline Power: 595 HP / 529 TQ

GPI LS3 Ported Rod Mod Manifold

Next we installed our GPI – LS3 Intake Manifold Mod (Radius Rod Mod / Porting) with the stands removed, floor epoxied and ½” radius rods installed at the top of the runners helping the air to make it’s required hard 90 deg turn in route to the cylinder.

As usual we picked up 10-12 hp across the entire RPM range.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,000-7,000 rpm) | Avg TQ (5,000-7,000 rpm) |

|---|---|---|---|---|

| Stock LS3 Manifold | 595 | 529 | 559 | 495 |

| GPI Ported & Rod Mod LS3 Manifold | 606 | 533 | 571 | 503 |

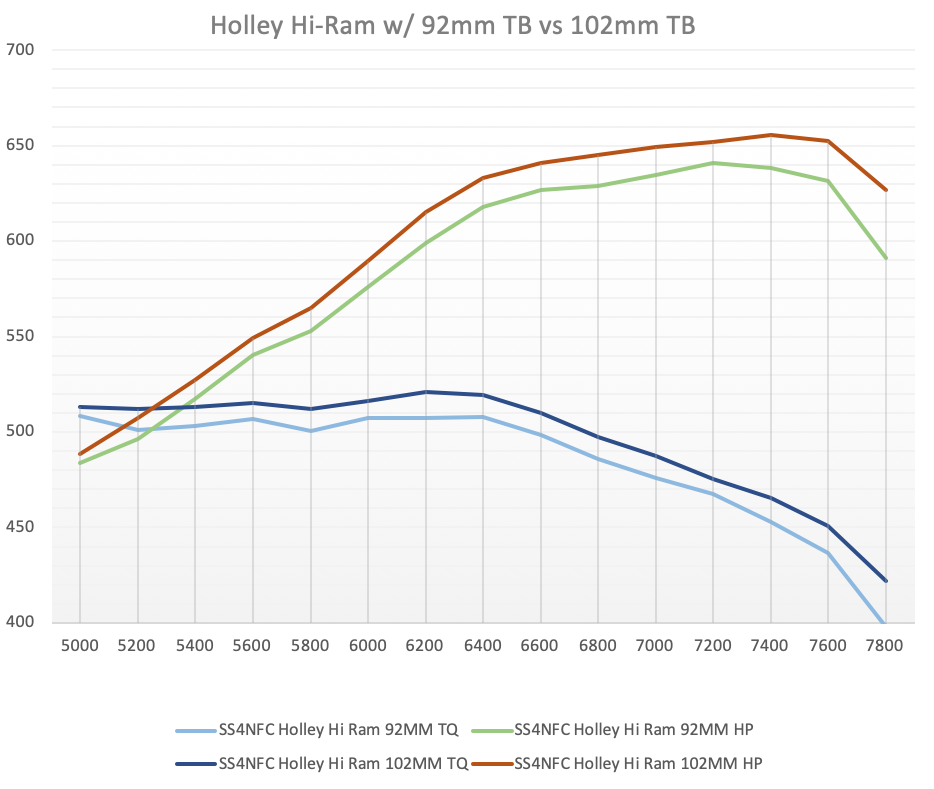

Holley Hi-Ram w/ 92mm TB

Next, we had planned to install the Fast 102 manifold with standard runners, but we had to change our plans as we neglected to procure any injector spacers (which are necessary on this manifold to run the LS3 short injectors with a stock fuel rail). We burned some daylight attempting to scab together a billet rail without proper bracketry only to concede and overnight some spacers!

What the heck, we will just install the Holley LS3 Hi-Ram (300-117) which conveniently includes fuel rails which work with the short injectors. (Be sure however and have a nice supply of every color of injector O-ring ever made because everyone who makes a manifold insists on making their hole a different size!)

In a matter of minutes, we had our Holley LS3 Hi-Ram (300-117) installed with a 92mm Throttle body and set up the dyno for a 5K to 8K pull. The Holley LS3 Hi-Ram (300-117) did its job as a short runner manifold which is to move the power band higher. We immediately observed what we had learned during a spintron session which is the Brian Tooley Racing – .660″ Lift Platinum Valve Spring Kit for LSx Engines (SK001) we were running lose control of the LS3 valvetrain at about 7800 RPMs. (This set had some use in a previous test, so they seemed to be giving up a little earlier than that. The intakes performance is accurately reflected to 7600 but the drastic drop after should be credited to the valvetrain for the remainder of the tests.)

Holley Hi-Ram w/ 92mm TB vs 102mm TB

We then fit the Holley LS3 Hi-Ram (300-117) with a 102 mm throttle body. We usually see insignificant gains on the chassis dyno between a 92 mm and 102 mm (on power levels under 570 rwhp, where an air box is part of the induction system), but the 102mm TB really woke things up on the engine dyno – picking up 8 to 15 across the entire RPM range.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600 rpm) | Avg TQ (5,600-7,600 rpm) |

|---|---|---|---|---|

| Holley Hi-Ram w/ 92mm | 642 | 511 | 607 | 485 |

| Holley Hi-Ram w/ 102mm | 655 | 525 | 622 | 497 |

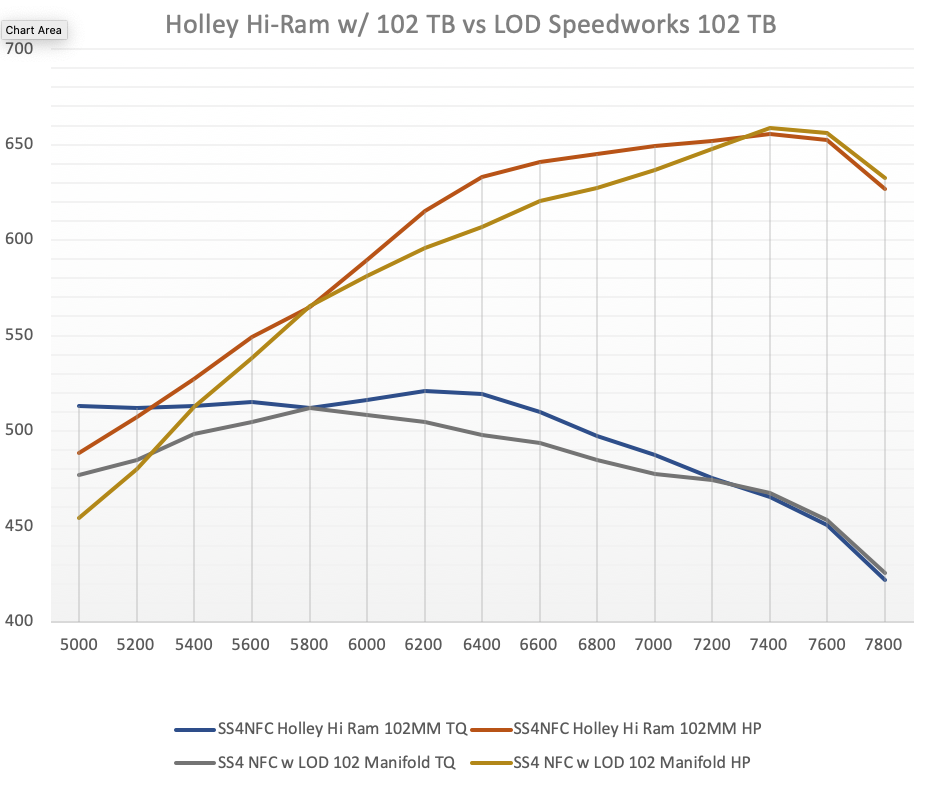

L.O.D Speedworks X1 w/ 102mm TB (no longer available)

Next Raf with L.O.D. Speedworks was kind enough to cruise up from Houston and bring us one of his L.O.D. Speedworks – X1 Intake Manifold for LS3 for further validation. He pulled in just as we were making our final pulls on the Holley LS3 Hi-Ram (300-117) so his timing was spot on. We promptly installed the L.O.D. Speedworks – X1 Intake Manifold for LS3 with a 102MM throttle body and made a rip.

Low and behold – we watched as it slightly out peaked the Holley LS3 Hi-Ram (300-117) with the same throttle body. Raf smiled and told us it would get better with the bigger cam we planned to install later. The power curve of the Holley LS3 Hi-Ram (300-117) is more robust than the L.O.D. Speedworks – X1 Intake Manifold for LS3 by 25 hp or so at 6,400 rpm, but by 7,400 rpm the L.O.D. Speedworks – X1 Intake Manifold for LS3 is ahead. I have no doubt it would have continued to hold its head up beyond 8,000 rpm on an engine with a valvetrain to support it.

We are thinking this manifold would be a great choice for customers wanting to do a solid roller and keep their hood and cowl. Perhaps we can test that combo in the future. They have also designed it to accommodate a cooling brick for you forced induction folks.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600 rpm) | Avg TQ (5,600-7,600 rpm) |

|---|---|---|---|---|

| Holley Hi-Ram w/ 102mm | 655 | 525 | 622 | 497 |

| L.O.D. Speedworks X1 w/ 102mm | 658 | 512 | 611 | 487 |

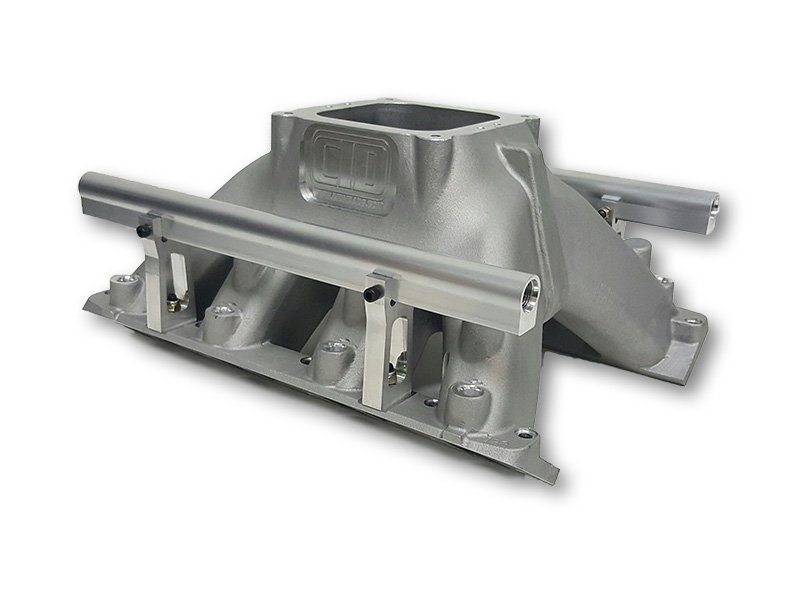

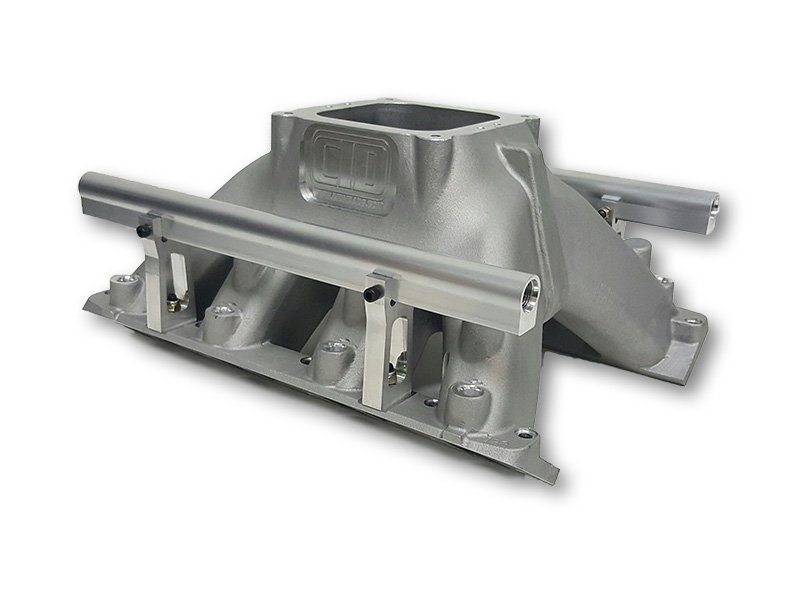

CID BE 4.0 LS3 Intake Manifold

Next up is the CID – BE 4.0 LS3 Intake Manifold. 9.24″ Deck. 4500 EFI. We installed this manifold with a 90 deg elbow and 92 mm throttle body first, then a 102 mm throttle body, and last a 4500 4-blade throttle body.

For a Max effort build this manifold gets it done. (One thing to remember is to check port alignment. CID leaves enough material on the flange to allow engine builders to properly fit the manifold to their applications.) We milled .130 and used a .030 gasket for proper runner alignment. The CID with a 4 barrel throttle body as expected, won the day producing 668 hp at 7,400 rpm’s. At this point we wrapped up our first day of testing.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600rpm) | Avg TQ (5,600-7,600rpm) |

|---|---|---|---|---|

| Holley Hi-Ram w/ 102mm | 655 | 525 | 622 | 497 |

| L.O.D. Speedworks X1 w/ 102mm | 658 | 512 | 611 | 487 |

| CID w/ elbow & 92mm | 651 | 513 | 606 | 484 |

| CID w/ 4500 TB | 671 | 527 | 629 | 502 |

FAST LSXR 102 Intake Manifold

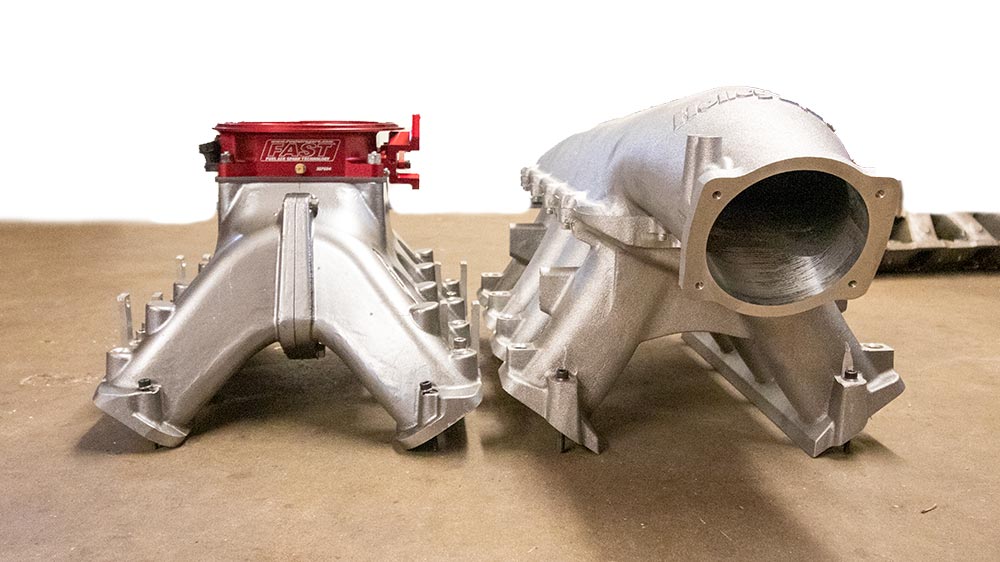

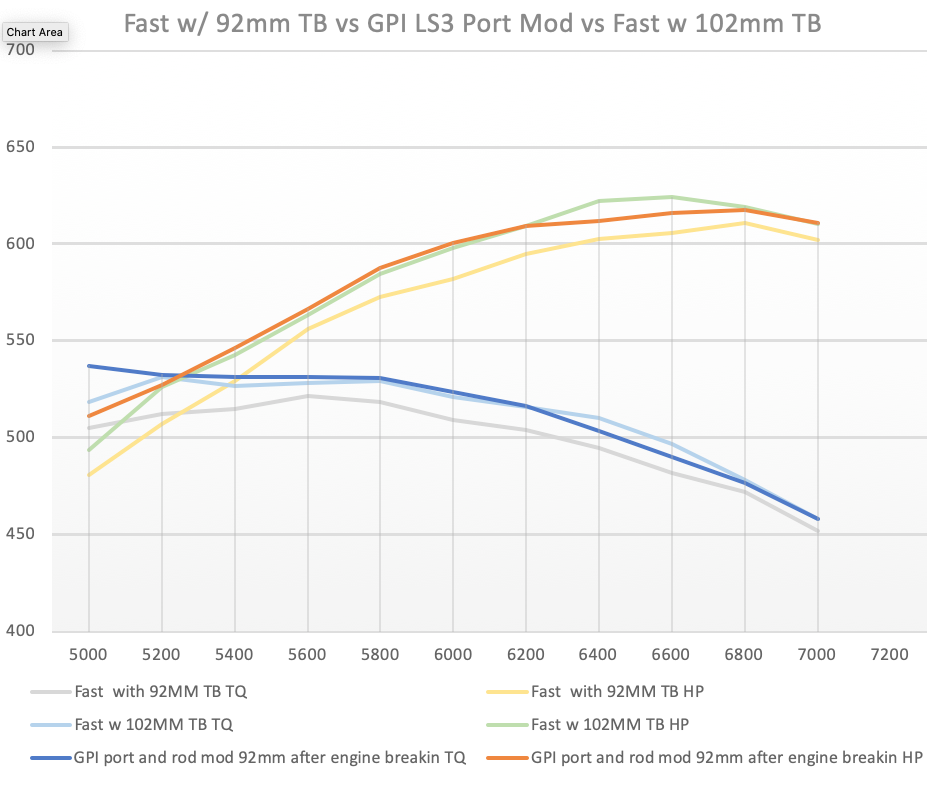

Armed with our injector extensions, we began day 2 by installing the FAST – LSXR Intake Manifold 102mm Intake Manifold for LS3, L99, L92, L76 (146302B) with a 92MM throttle body. We were surprised when it made a tick more power than our GPI – LS3 Intake Manifold Mod (Radius Rod Mod / Porting) tested the day before, so we reinstalled the GPI – LS3 Intake Manifold Mod (Radius Rod Mod / Porting) and ran it again back to back for a more accurate comparison. Low and behold, the numbers were up on it as well. (We assume our engine was still breaking in when we ran the GPI – LS3 Intake Manifold Mod (Radius Rod Mod / Porting) as the second test of day one.)

We then reinstalled the FAST – LSXR Intake Manifold 102mm Intake Manifold for LS3, L99, L92, L76 (146302B), repeated the results with the 92 mm TB, and moved forward installing the 102 mm TB to determine its effect. That got it over the hump, and it bested the GPI – LS3 Intake Manifold Mod (Radius Rod Mod / Porting) briefly by about 8 hp at 6400 and 6600 RPM. A rather large investment for a small return in our opinion at least with the cam / compression combo.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,000-7,000 rpm) | Avg TQ (5,000-7,000 rpm) |

|---|---|---|---|---|

| GPI Ported & Rod Mod LS3 Manifold (after engine break in) | 617 | 544 | 582 | 511 |

| Fast w/ 92mm TB | 611 | 531 | 567 | 498 |

| Fast w/ 102mm TB | 625 | 538 | 581 | 510 |

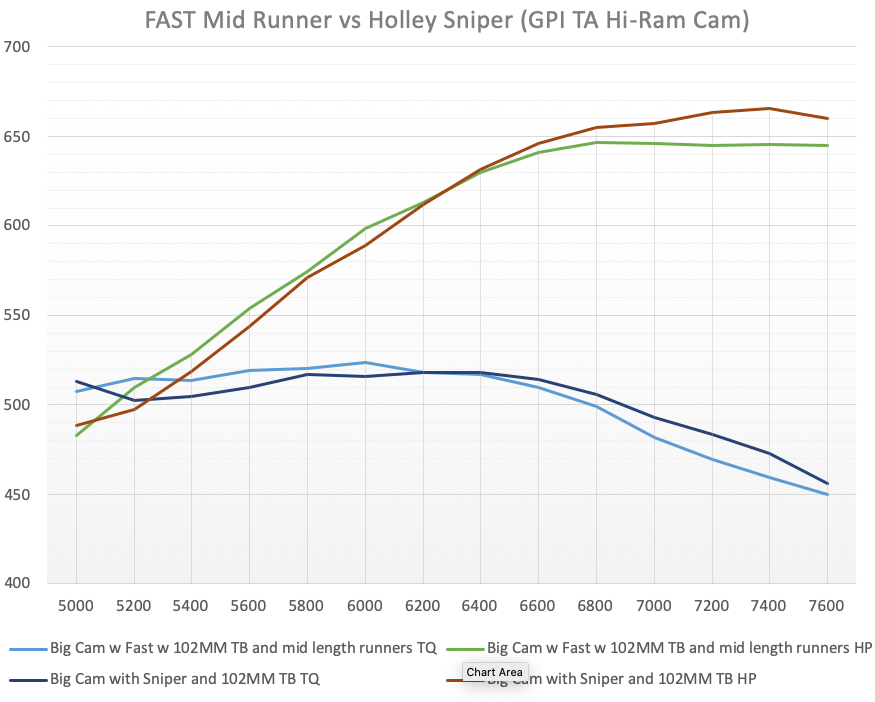

Holley Sniper Intake Manifold (w/ Big Cam)

It was then time to see how some of the short runner manifolds would respond when combined with a more aggressive camshaft so we slid in a 244/268 on a 108, changed to the medium length runners on the FAST – LSXR Intake Manifold 102mm Intake Manifold for LS3, L99, L92, L76 (146302B) and let the games begin. We followed that up with a Holley Sniper EFI Fabricated Intake Manifold LS3/L92 we had sitting on the shelf which had disappointed us several months ago when bolted on a 416 with a mid 240s duration cam in a Camaro. We were a bit surprised as it performed very well, besting the FAST – LSXR Intake Manifold 102mm Intake Manifold for LS3, L99, L92, L76 (146302B) from 6600 RPMs and beyond by as much as 14HP with little sacrifice below. Maybe we will wipe that thing down and sell it now!

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600 rpm) | Avg TQ (5,600-7,600 rpm) |

|---|---|---|---|---|

| FAST LSXR High HP Intake Manifold Runner Manifold | 650 | 519 | 621 | 496 |

| Holley Sniper | 667 | 522 | 626 | 499 |

L.O.D Speedworks X1 Intake Manifold (w/ Big Cam)

It was time to bolt the L.O.D. Speedworks – X1 Intake Manifold for LS3 back on with more camshaft and see if the designer’s prediction held true. Sure enough after 7200 it certainly came on strong making 686 hp @ 7,600 vs 665 hp for the Holley Sniper EFI Fabricated Intake Manifold LS3/L92. Peak to peak it was worth 19 hp but once again illustrated how well it would work on a solid roller engine where it could be turned 8500 or so. Our Hydraulic mule simply didn’t do any of the short runner manifolds justice.

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600 rpm) | Avg TQ (5,600-7,600 rpm) |

|---|---|---|---|---|

| L.O.D. Speedworks X1 | 686 | 524 | 625 | 499 |

| Holley Sniper | 667 | 522 | 626 | 499 |

All Short Runner Intake Manifolds Compared (w/ Big Cam)

We then retested the Holley LS3 Hi-Ram (300-117) and the CID – BE 4.0 LS3 Intake Manifold. 9.24″ Deck. 4500 EFI with the larger camshaft.

The following graph overlays the 4 short runner offerings. The CID – BE 4.0 LS3 Intake Manifold. 9.24″ Deck. 4500 EFI dominated even with the insufficient hydraulic valve train gapping the Holley LS3 Hi-Ram (300-117) by 15 hp (692 hp to 677 hp).

| Intake Manifold | Peak HP | Peak TQ | Avg HP (5,600-7,600 rpm) | Avg TQ (5,600-7,600 rpm) |

|---|---|---|---|---|

| L.O.D. Speedworks X1 | 686 | 524 | 625 | 499 |

| Holley Sniper | 667 | 522 | 626 | 499 |

| Holley Hi-Ram | 677 | 533 | 634 | 506 |

| CID w/ 4500 | 692 | 535 | 643 | 513 |

This concluded our LS3 testing, we hope the information we verified will be useful to our fellow LS enthusiasts and customers.

Stay tuned for our upcoming LS7 top end testing.

Thanks,

GPI Team

I have the SS4 no fly cut camshaft. Im wanting the the 2nd camshaft in this test. Is it a custom grind? if so are you able to share the specs.

Yes its a custom grind, I would recommend filling out our custom cam worksheet on the website and having Ryan spec you a cam for your set up https://gwatneyperformance.com/product/gpi-custom-cam-worksheet/

Have you ever dyno’d the carbon design stuff for ls 1,2,3,7

Excellent article. Would love to see these manifolds with the Victor Jr, Super Vic, and the new Fast tunnel ram in the near future. As someone that understands how much work is involved with this testing, thank you.

Not everyone has a slushbox, some of us still remember how to use a clutch. 😉

Also, we’re not all drag racers. I like curves too.

I agree with Joel, more data would be nice.

Thank you guys for the feedback.

You’ll have to bear with us this time, because this is the data we captured. On our next tests we will collect a larger RPM range based on feedback!

What were the results with the 102mm TB on the CID intake ?

Can you please show the full curves? I care a great deal about differences at 3000 rpm. Hell, 2500 rpm is the “accelerate-without-down-shifting” sweet spot and I want to know how badly it lugs. I know sometimes folks start at 3500, but 5k? As-is, you clipped off the peak torque value on a bunch of your tests! Even if you don’t have traces for everything that low, it would really help those of us who care.

Hey Joel,

Both of the cams used in the testing peak tq over 5000 RPM and would require that much torque converter to be ideal. Pulling below 5000 RPM is of no value to us on combos that spin 7500 plus RPM. You can not have power at 7500 and 2500, so we pulled the engine in the appropriate RPM range suitable for these combinations. Average power in the intended power from 5000-8000 is what we were after.

Stay with a long runner plastic manifold if you want the best low end power curve, our ported LS3 intake etc..