It seems a lot of questions, concerns, information and misinformation exists related to the LS7 valvetrain issues.

We felt it might be helpful to our dealers and customers to summarize what we have learned over time about these issues.

(Want to skip straight to our Ported OEM LS7 Cylinder Head Package?)

-

GPI – LS7 HeadsFrom: $1,195.00

GPI – LS7 HeadsFrom: $1,195.00

THE INFAMOUS CONCERN

I just purchased a C6 Z06 and I am reluctant to drive it before getting the “heads fixed”…

THE HUNT FOR KNOWLEDGE

The concern often seems to arise from the “Forum Chatter” – where a high percentage of customers who actually experience an issue – go to seek info and share their grief.

(I am certainly not judging – as this is perfectly natural – I am just pointing out that statistically, the number of horror stories are probably disproportionate to the total number of LS7 engines operating flawlessly for many miles.)

FROM OUR EXPERIENCE

We have seen exhaust valves become separated from their stem resulting in mass destruction – but have yet to see it on a completely stock engine.

(I am not suggesting it hasn’t happened – only that our experience has indicated that it seems much more problematic in modified engines, where more aggressive ramp rates increase the likelihood of “loft and bounce” during high RPM operation.)

LS7 VS THE “OTHER” LS HEADS

As we examine the the LS7 cylinder head in comparison to the other LS configurations – which rarely have valve or guide issues – we find the following differences:

- 12 degree (LS7) vs 15 degree (LS3 / L92) valve angle

- Higher intake runner (LS7) which improves the airflow path while at the same time requiring a longer valve and greater unsupported stem area between the valve head and the bottom of the guide.

- 1.8:1 rocker arm ratio vs the 1.7:1 ratio found on its LS counterparts

- Ultra-light weight titanium intake valve and a hollow sodium filled exhaust valve.

We don’t feel the smoking gun is found in any one of these differences – but, some of them culminate to create the issue that keeps so many LS7 owners awake a night.

GM’S RESPONSE

General Motors released a technical service bulletin stating:

…it was determined that a machining error in the valve guide had occurred at our head supplier.

I have a hard time buying into this one – as I seriously doubt they finished the guides in the shape of an oval (as we find in a typical “out of spec” LS7 guide).

At minimum Ford would complain about logo infringement…

TOP 3 THEORIES WHY LS7’S FAIL

THEORY #1: HIGH LIFT CAMS & STOCK ROCKER ARMS

When we looked closely at the rocker to valve tip sweep pattern we find the stock steel radiused rocker takes a trip across over 60% of the of the valve tip or lash cap as it were.

It’s a simple and light design that works fairly well when the valve lift stays under .600 as GM intended. When we increase that lift however, the valve is subjected to greater side loading.

Effect: Sideloading on the valve, causing additional wear.

THEORY #2: EXCESSIVE VALVE COATING WEAR

The next theory is that the manufacturer of the titanium intake valves failed to get the chromium nitride coating right in some instances – resulting in the increased guide wear.

While it’s true that titanium hates everything except titanium, I am more prone to believe the coating simply wears through due to excessive side load, which then allows the titanium to go to work on the remaining guide.

Effect: Increased abrasion from exposed titanium.

THEORY #3: LONGER VALVES, SAME LENGTH GUIDES

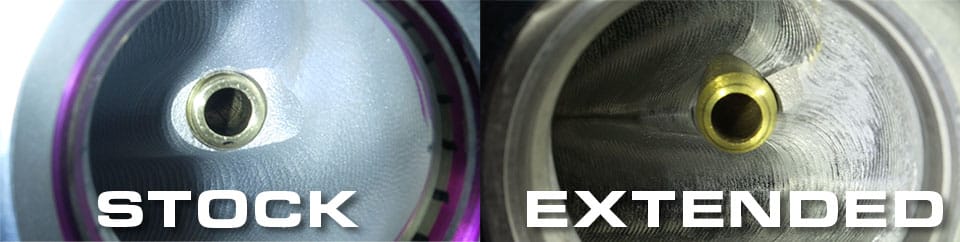

In our opinion the third contributing factor is the length of the guide versus the length of the valve. The guide is the same length as the Other LS engines but the valves are longer. Nearly all the additional length is between the bottom of the guide and the valve seat.

Effect: You get the idea…

TOP 3 WAY TO BULLETPROOF YOUR LS7

RESOLUTION PT. 1: EXTEND THE VALVE GUIDE

We have found no appreciable flow reduction after extending the guide an additional .250 into the runner providing additional stability.

RESOLUTION PT. 2: IMPROVED GUIDE MATERIALS

Concerning the guide material, the powdered metal guide is a very durable material that works extremely well on LS heads everywhere. On a street engine that doesn’t get torn down every season it is far superior to a standard bronze guide.

We feel the material itself is not a contributing factor, however manganese bronzanium 90 guides extended further into the port have proven an excellent solution during our endurance testing.

RESOLUTION PT. 3: UPGRADED ROCKER ARMS

Rocker arms play a major role in a high performance valve train and also come at a price, currency being one form and mass being the other.

We have studied most of the options currently available for the LS7 and will attempt to provide some insight.

A roller tip rocker when in a proper geometric configuration does a phenominal job of reducing side load on the guide and directing most of the energy towards the task of opening the valve. In high performance and racing applications where cost and complexity aren’t as negative a factor as in mass production manufacturing they are very desirable.

The challenge on the LS engine however is:

- designing a rugged component within the space constraints of the valve cover rails and height

- designing a structure that can properly support a roller and axle without adding a lot of mass between the fulcrum and the tip – which ultimately must be controlled by the valve spring

Roller Rockers (Shaft mount)

For solid roller applications, the shaft mount offerings from Jessel and Crower are our picks (as the mounting girdle distributes the load more reliably over the head casting vs. the cast stand bearing the burden).

We run:

- Jessel on OEM style castings after milling the stands down

- Crower on Brodix BR-7 big spring castings

Roller Rockers (Bolt on)

Concerning the bolt on products available we have tested Harlan Sharp, T&D, and Yellow Terra.

(Jessel offers a bolt on piece but when given the option of buying a vacation home on the coast or a set of rockers for testing, we had to make a choice. Seriously. $200.00 per rocker!)

We checked net lift on all the brands and found the sweep pattern and ratios to be acceptable. All slightly over ratio as I am sure is by design. Most customers won’t take issue with a tic more lift but don’t give them less!

Harlan Sharp

Out of the three, the bulky aluminum body Harlan Sharp SLS78A, was the only true bolt in so far as not having to clearance anything on the stock casting. We did have to dust a corner off with the belt sander on two end intakes and two exhausts when using on a BR-7 casting due to a slight difference in the valve cover rail.

These are a fully adjustable rocker and can be used with a solid roller. They will require a taller valve cover as do all of the adjustable solutions.

T & D

The T&D 15015 stock eliminator rockers are more expensive, but are a very nice piece. Billet steel construction yet very light where it counts. We had to clearance the upper valve cover rail even on stock castings, otherwise they are good to go.

Yellow Terra

The Yellow Terra which is advertised as retaining the stock cover was a bit more of a challenge. They are non adjustable and use a .125 thick hex nut and a thicker gasket to gain the needed cover clearance. I tested them on a .648 lift set up by putting a dial indicator on the cover and rolling the engine over using the stock gasket and measured .152 movement, so the math tells me a valve cover spacer or tall cover would be necessary.

The other issue we ran into was we had to relieve one side of the bottom of the stand otherwise they lock up when they get close to seating on the stand. We tried 2 different sets of castings and one set was worse than the other but both needed some work. I am sure due to some core shift it’s not the case on every set of heads but still noteworthy.

IN CONCLUSION

The way we sleep best at night as it relates to LS7 top ends is as follows:

- Valve Guides:

- Powdered Metal Guide or Bronzanium 90 Guides

- .250 longer properly fit to spec

- Rocker Arms:

- If stock rockers are used:

- Lift at .630″ or less, and true the tips.

- Micro-polished and bronze bushed is a nice option on the stock rockers – although we have seen few GM trunnion bearing failures where some type of trauma was not the root cause. (We have seen more failures with the trunnion bearing kits where the trunnion material doesn’t appear hard and or smooth enough to act as a bearing race. The OEM bearings have a hardened steel inner race to provide the needle bearings a nice surface to run on. For that reason we sell only bushing kits).

- If roller rockers are used:

- Refer to our findings provided earlier.

- If stock rockers are used:

- Intake Valves:

- Polish and coat the original Del West intake valves.

- Exhaust Valves:

- REV offers a nice solid stainless 1.614 exhaust valve that’s affordable and totally adequate for most street applications. (It weighs in about 18 grams heavier than the F2042P but is still under 100 grams).

- Ferrea F-2042P-8 exhaust valves for N/A applications.

- We like the Ferrea F-1597P-8 for forced induction applications.

- Valve springs:

- Will vary with intended use and cam spec.

- Lash Caps:

- Don’t forget the lash caps on the Del West Titanium intake valves.

CHECK OUT OUR COMPLETE LS7 PACKAGE!

Our LS7 Cylinder Head Package solves all of these durability concerns – while improving power and torque across the power band. If you are a concerned LS7 owner – this is a no brainer.

-

GPI – LS7 HeadsFrom: $1,195.00

GPI – LS7 HeadsFrom: $1,195.00

Just bought a 2006 Z06 with 17,500 miles and since learned of the valve guide issue. Now I’m scared to drive it as I’m retired and do not want to be on the hook for a new engine. Can’t decide best way forward as I don’t want to take it to the dealer to have the wiggle test performed and don’t know of a good independent shop in my area. Do you know of a shop in NE Ohio?

if you haven’t found a shop try Hutter Perfomance in Chardon.

I have 3900 miles on an LS7 2009 Corvette. I want to put the best products into the current valve train and use my intake and valve heads. I want the best valve guides rollers chromoly push rods and anything else you can do to the top end to ensure reliability and make it bulletproof as well as make it flow as best as it can I might put a 630 to 650 cam and I’m wondering what would be the best product for your valve train build as far as a cam that’s not going to be radical as far as idle is concerned but might add maybe 75 more horses with the whole project. I will be adding cook headers and a 3-in x pipe with free flow cats. I do want the best exhaust valves that you offer. I know it’s critical to have balance in the valve train and I don’t want to add additional grams with the stainless exhaust I was thinking a titanium exhaust with titanium retainers and clips as well any idea what the cost would be if I sent in my heads and had you freshen everything up as well as a 10,000 mil job.

Cost on this would be $2,309.00 with upgraded valve guides, upgraded valve springs, upgraded exhaust valves

Ferrea – LS7 Exhaust Valve, Stainless Steel, Hollow (F2042P) (NA Builds)

Gwatney Performance :

Long before I came across this article of yours, I essentially chose to leave my 2007 LS7 now with 58,000 miles, STOCK. All I did was add an Edelbrock E-force supercharger for 200 more horsepower. Been trouble free now for the 5 years since installed… and still wind to 7000 RPM when the mood strikes.

I don’t fix what ain’t broke, so your info in the opening paragraphs of your article should be required reading before anyone spends buckets of money to screw up a well engineered GM jewel.

Thanks.

LS7 will go down in history as one of the best. Glad you are enjoying it!

Hello from New Zealand. I am waiting for my 2007 Z06 to arrive in the next couple of weeks. The vehicle has been treasured and only has 27k miles on it. I am quite paranoid about this problem because at 68 years of age (and retired), I see this as my last ‘hurrah’ as far as hot cars is concerned. Thank you for a most informative article….will definitely invest in the upgrade.

Very welcome Rob. Glad we could help!

Rob

Hi

I am in Auckland and looking to import a Z06 later this year, where did you get the valves done in NZ?

Or is it better to do these state side

Cheers Steve

Do you sell the 1/4″ longer Bronzanium (being a tool and diemaker for over 40 years, just what is Bronzanium, anyway? Never heard of it…) 90 guides? If so, how much?

I’m hearing that by the 2013 model this was no longer an issue.

True?

From the “independent studies” we’ve read – the occurrences became ever so slightly less frequent as the years went on. Hard to know if it is just based on lower mileage on lower engines or improved components/processes.

I have a 2009 Z06 just bought it . I’m keeping my car stock it’s used with 60 k miles so I don’t know whats been done before me . But I’m hoping I obviously don’t g through this . Is there away to just have it checked by removing the valve covers .? either way nice article , great information .

It is fairly common for a customer to bring their Z06 in for us to check the valve guide clearances. We air up the cylinder with a leak down tool, the same way you would change valve springs, remove the spring. Set up the dial indicator on the valve stem. Check side to side movement. We usually check 3-4 cylinders and you can get a pretty accurate average of whats going on.

Good article. I had the same thoughts. Wish I saw this before but my car is all stock at this time. Although Frankenstein for example has aftermarket casting that are nice, the valve angle is 10 Deg or 15 deg and requires new valve covers. They can fix the factory heads too. and we use reuse the existing intake valve but will swap out the exhaust valves for stainless. I didn’t know what the weight difference it. maybe 30% or maybe less. But it is an issue to keep the valve train about the same weight.

Makes total sense — going outside of the factory ‘design’ specs should indicate the need to do more than just ‘pop’ in a cam and springs.

As far as the LS7, I don’t believe this was an issue with the engines installed in the 14/15 Z/28s — unless someone went ‘large’ on the cam.

This is why GPI is a leader in the performance arena.

I’m looking forward to seeing more articles from you